DIN 18202

Section 5 of the German DIN 18202 (General Building Specification) relates to flatness tolerances of the surfaces of floors, ceilings, screeds and walls. Group 3 and 4 of Table 3 relate to finished floors and gives the deviation limits for variable gauge lengths.

Table 3: Flatness tolerances

| Column | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Group | Applicable to | Position deviations (limit values). In mm, for distances between measuring points, in m, up to | ||||

| 0.1 | 1 * | 4 * | 10 * | 15 * † | ||

| 1 | Unfinished upper surfaces of floors, subfloors and concrete bases. | 10 | 15 | 20 | 25 | 30 |

| 2 | Unfinished upper surfaces of floors, subfloors and concrete bases subject to more stringent requirements (e.g to receive floating screed, industrial floors, tile flooring and bonded screed), and finished surfaces for minor purposes (e.g. in storerooms or basements) |

5 | 8 | 12 | 15 | 20 |

| 3 | Finished floors (e.g. screed as wearing courses or screed to receive a flooring, trowelled or bonded floorings) | 2 | 4 | 10 | 12 | 15 |

| 4 | As group 3, but subject to more stringent requirements | 1 | 3 | 9 | 12 | 15 |

| 5 | Unfinished walls and unfinished ceilings | 5 | 10 | 15 | 20 | 25 |

| 6 | Finished walls and ceilings (e.g. plastered walls, wall claddings and linings, suspended ceilings) | 3 | 5 | 10 | 20 | 25 |

| 7 | As group 6, but subject to more stringent requirements | 2 | 3 | 8 | 15 | 20 |

Table 3 indicates 5 lengths to consider; 0.1m, 1.0m, 4m, 10m and 15m. In contrast a graph on the following page of the document (figure 1) shows an infinite number of gauge lengths which can be used to check compliance with the specification, checking them all would be cost prohibitive. Face Consultants therefore decided that our Din Meter would check compliance with 3 gauge lengths; 1m, 2m and 4m mean lines.

How the deviation from the mean lines is calculated is explained in our Further explanatory information document.

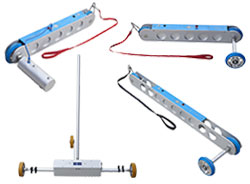

DIN 18202 does not specify how to conduct a survey to check compliance with these limits should be conducted. It can be checked using straightedges of the appropriate length or by using an optical level; but both of these processes are relatively imprecise and extremely laborious. For continuous measurement of DIN 18202, the FACE DIN Meter is used: the DIN Meter is a wheeled instrument that travels across the floor taking continuous readings as it does so.

An easily legible graph is produced for each mean line – when the floor complies with the limits defined by the specification the graph is green and when it does not comply, the graph is red.

Note: In Table 3, Groups 3 and 4 relate to floor flatness, the rest is a general building specification.

Related Documents

The Face DINmeter

The DINmeter can be used to quickly survey a floor to the DIN 18202 specification. Data is collected by the device before being downloaded to a handheld device for analysis.

DIN 18202 Compliance Testing

Face Consultants specialise in compliance checking floors to DIN 1802 using advanced digital measuring equipment for fast and reliable data.

Contact us now to book your survey.

Measurement Standards

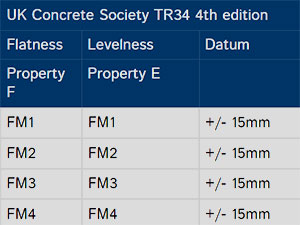

TR34 4th Edition

The Concrete Society’s TR34 Free Movement (4th Edition) Classifications

(Current Version)

DIN 18202

Surface Regularity

can be checked to ‘BS 8204-2:2003+A2:2011’ straight edge specifications SR1, SR2 and SR3

TR34 3rd Edition

The Concrete Society’s TR34 Free Movement (3rd Edition) Classifications

(Previous Version)*